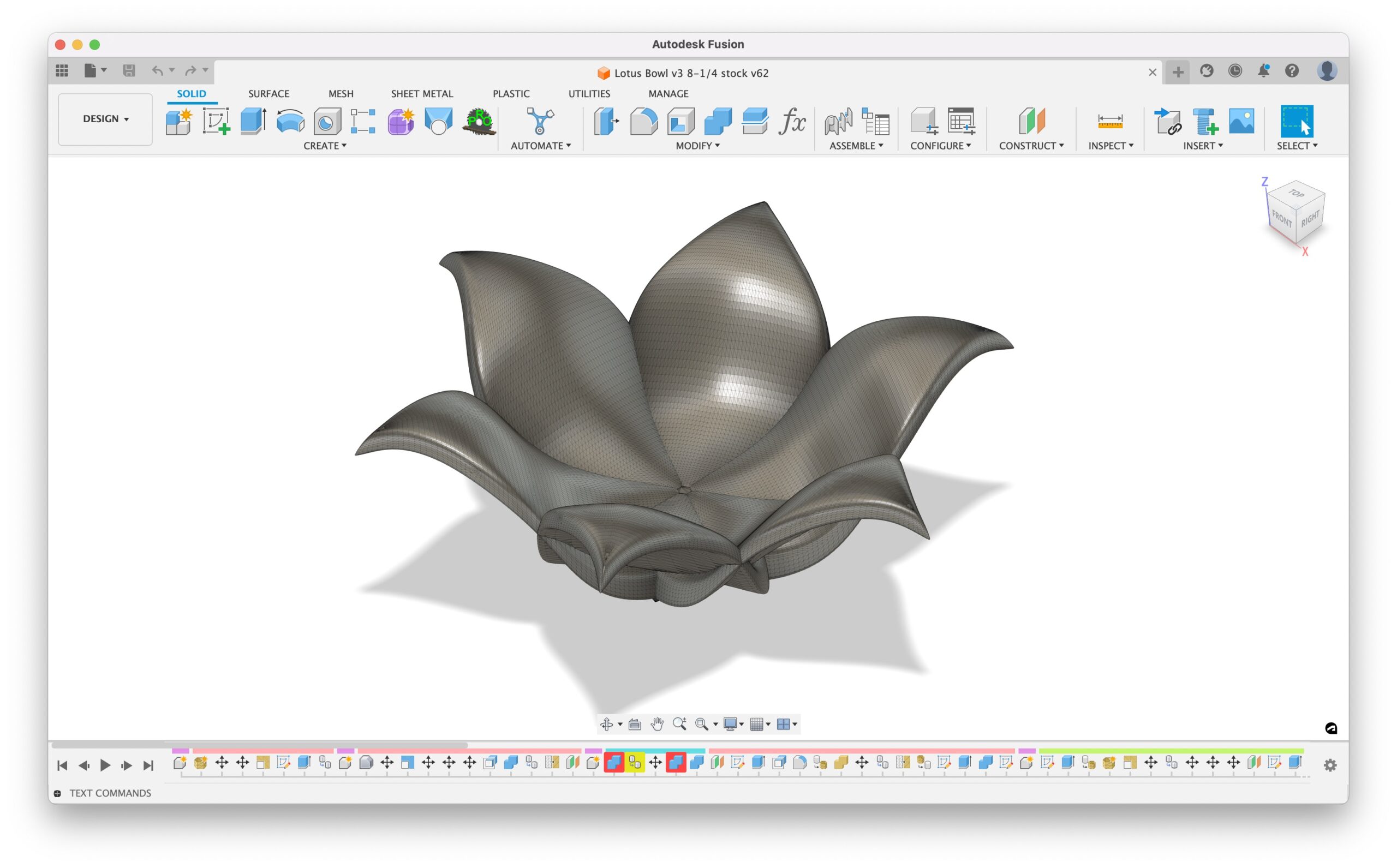

These are the digital files I created to make my “Lotus Bowl” on a CNC machine. Included is the complete Fusion 360 file with all my toolpaths setup for my Tormach PCNC 1100. For any other CNC, you will have to change the speeds and feeds! If you don’t use Fusion 360 I am including the exported STLs for importing into other CAD/CAM software, such as Vectric VCarve or Aspire.

Before purchasing, please watch the build video: Lotus Bowl Video

NOTE: No directions are included! I usually like to make step by step directions, but I did not do it for this project. This is an advanced CNC project.

The Fusion 360 file is large at 54 MB. Beware that it may take a while to download.

Included in the download:

- Lotus Bowl Fusion 360 v62.f3d — The Fusion 360 file

- Lotus Bowl.stl – the main bowl shape

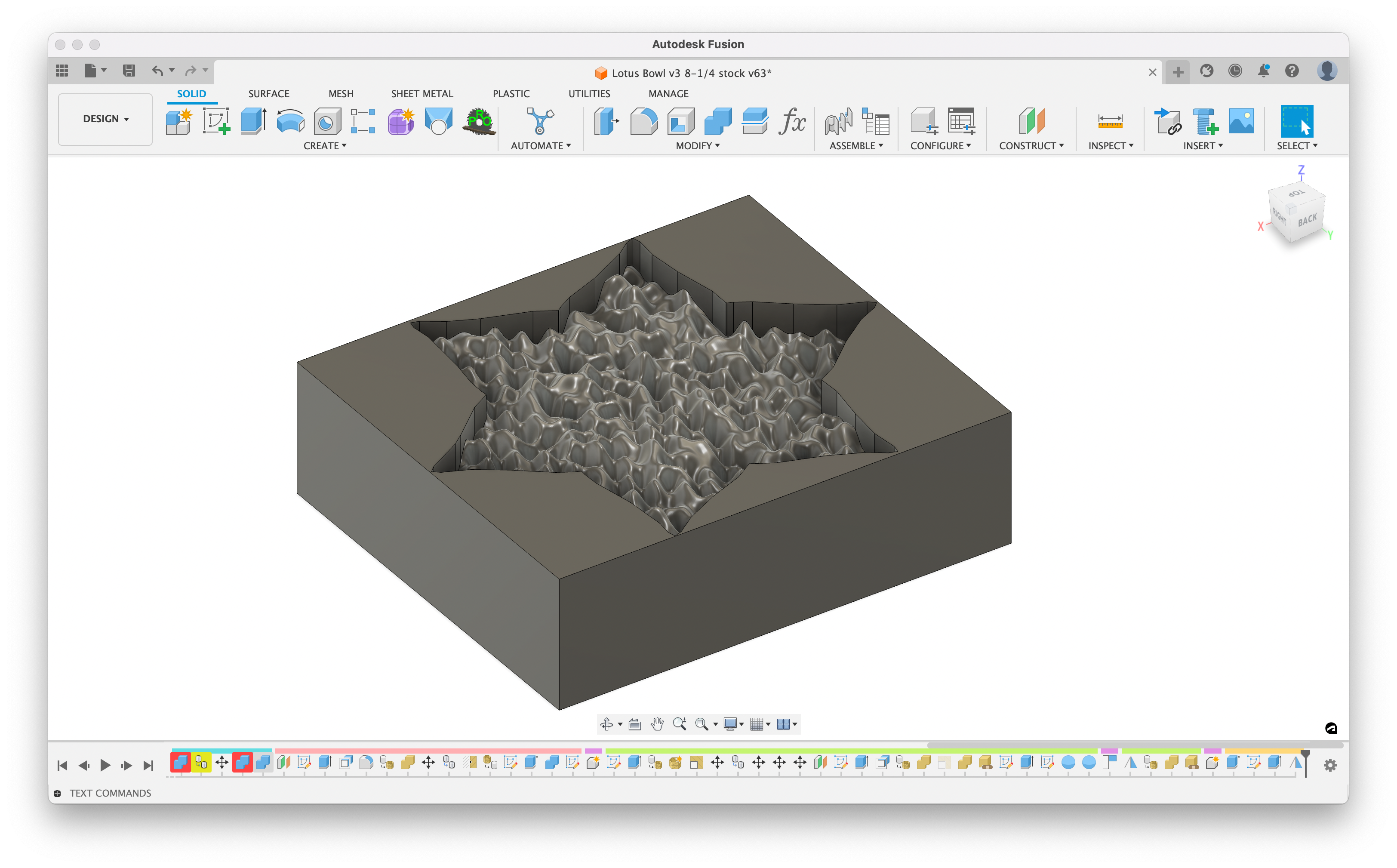

- Lotus Bowl Mold.stl – the ‘mold’ used for pouring epoxy into

- Package Bottom.stl – The packaging shape

- Package Lid.stl – Packaging lid

- Lotus Bowl Notes v1.pdf – Just some notes and material lists

I’m including the STL and model for the “Package” which I made out of foam to hold the bowl for shipping. The Blender file which

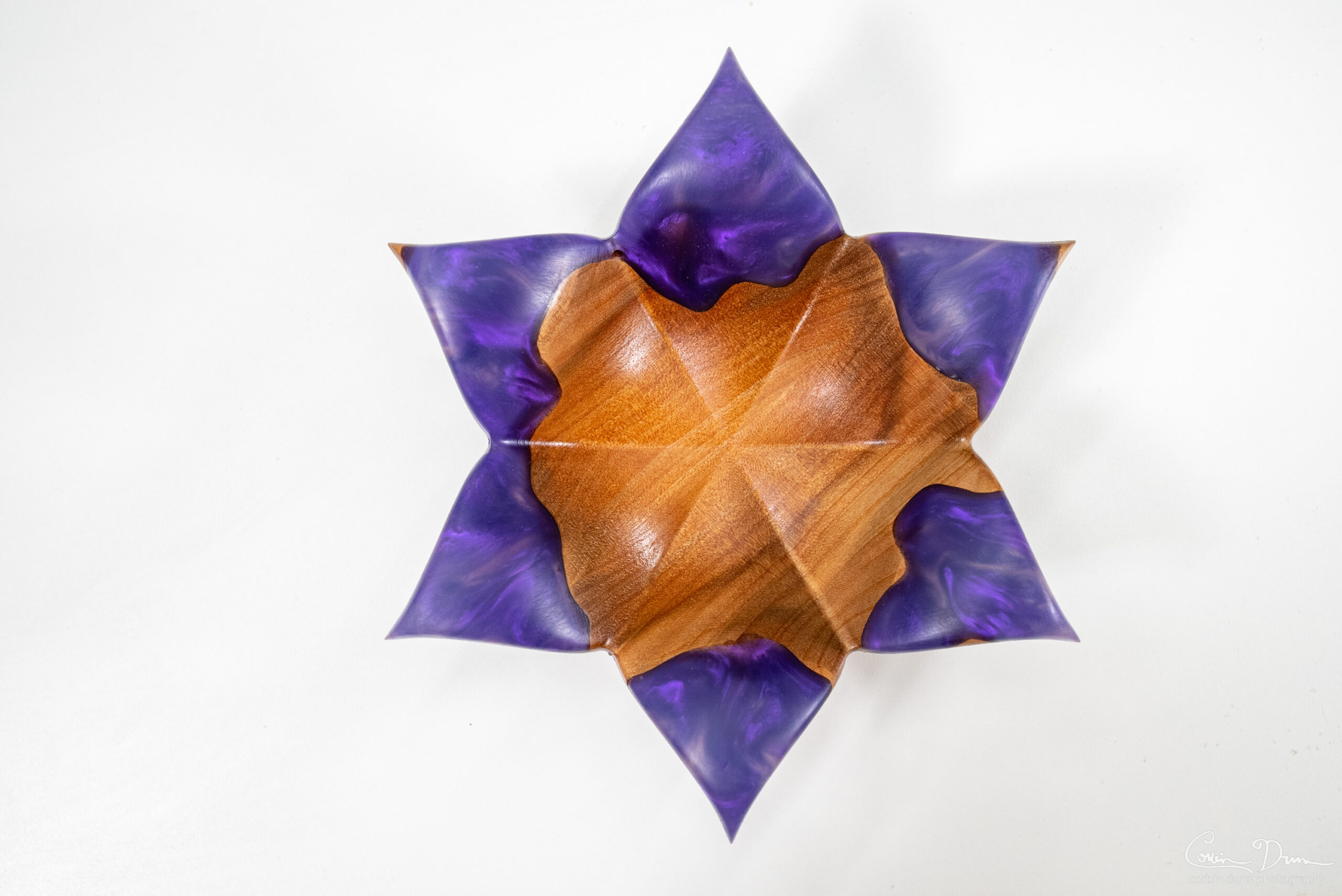

Photos are from the several ones that I made (three in total; one was sold to fund the others).

Fusion 360 Notes

The timeline has some “broken” elements in it due to me changing some sizes and moving things around. These were just for the rendering, which isn’t important for machining the base shape.

All the main bodies are under the “bowl” component. I prefer to model up the stock and place the bowl where I want it in the stock. Ideally each of these should be their own component, and this is just how I used to organize my older files. The “simplified” bowl mesh was for creating the packaging shapes.

Bonus: The The package shapes can be machined from foam.

The Manufacture tab has all my toolpaths setup for machining on my Tormach PCNC 1100, which has a very slow 5140 RPM — these feeds and speeds will need to be adjusted for your typical wood router CNC machine that runs at typical wood speeds (~18,000 RPM). All toolpaths are provided as-is, and I make no guarantee they will work for you. Please do simulations with your actual tool heights set to ensure you don’t get collisions.